Custom Build Capabilities

We started our business in the agriculture and industrial markets making equipment for local farmers, the local Cargill plant, the Iowa Department of Transportation, and the oil fields of Kansas, Oklahoma, and Texas. We understand that many times the standard pressure washer or sewer jetter is not going to do the job you have in mind. We also understand space is always an issue. We all want more performance and more power to fit in the space we have in mind, at a reasonable price… and we really could have used it last week! Your satisfaction becomes our satisfaction!

When we learn about your specific needs, we learn more about the industries we serve. Many times the custom pressure washer trailers we design for you become products we introduce for our standard line of equipment.

We have compiled a collection of custom pressure washers and machines we have built for customers like you that are striving to make each day easier and hassle-free. Browse below or call us today to build your own pressure washer with Cam Spray!

Custom built sewer jetting machine

Doug Kuettel called us from Kuettel Septic in Hortonville, WI, to talk about his needs for a new skid mounted pressure washer sewer jetter. He wanted 2700 psi at 11.5 GPM to be put in as little space as possible in a new truck he had just ordered. The truck was also equipped to do work other than jetting, so space was an issue. The new truck was dropped off at our facility by the dealer. And a nice truck it was: color matched metallic paint, fiberglass lined walls, custom lighting, and all stainless steel fixtures. To match, we used all stainless steel framework and fit everything in the space Doug requested. The truck came in on Monday, and was ready to go on Thursday afternoon. Customer satisfied, at last word Doug was talking about another new machine with more ideas to make each day easier.

Pressure washing in Food Processing & Pork Production

This custom pressure washer was designed for a multi-bay truck wash at a fructose corn syrup plant in Illinois. The plant needed a hot water pressure washer—they had a boiler system but the water temperature exceeded reasonably priced pump capabilities. Prior pressure washers proved inadequate due to uncontrollable inlet water temperatures and flow. Pumps capable of handling high inlet water temperatures and flows can be four to five times more expensive to purchase and repair than a standard industrial duty pressure washer pump. We designed a system to blend the boiler water and cold water to the desired temperatures (around 160°F) for pressure washing the exterior of the tanks and trucks. With minor modifications, this same model has found a home in the pork production industry thanks to the compact space saving design and ability to deliver varied rates of flow and pressure with multiple guns. Solutions equal satisfaction!

Railcar refurbishing needs heavy duty powerful pressure washer

GE Railcar is a facility that refurbishes railcars that have been hauling Portland cement for a number of years. A call came from our local distributor describing the application needing a pressure washer to tackle the job. Each time the railcar is loaded, some of the Portland cement remains on top of the car. Add a little moisture and the build-up on the top can be several inches thick. After several years of loading and unloading the cars, the Portland cement dust coats the entire outside surface of the car. A portable 7000 psi cold water pressure washerwas developed to remove this Portland cement coating prior to refurbishing. This model later became the standard 7000HXR pressure washer in our product line.

Mining Industry needs to keep drilling bits clean

This machine is an example of the work we do with original equipment manufacturers. This product is only a small part of a piece of equipment that costs millions of dollars. But without this key component, the job could not get done. This machine was a combined job between Cam Spray and a company that is involved in mining around the world. This machine is powered by a Hatz® Diesel engine and produces 4gpm at 3000psi. The machine is intergraded into the drill chassis with a stainless steel control panel mounted near the drilling tool area. This allows for efficient cleaning of the drill bits and drill rods while changing and servicing these components.

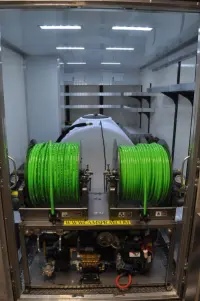

Hospital sewer lines must stay open at all times!

We got a call from a hospital in Kentucky for a custom pressure washer sewer jetter. The request was for an electric sewer jetter that would be installed in a small building adjacent to the hospital. The specifications were for water flow to be 60 GPM at 2000 psi with a 600’ x 1” hose on a powered reel to be used daily in the cleaning of the main sewer and drain lines under the hospital facility. A full day of training on operation, maintenance, repair, and troubleshooting was provided after installation. Built with a 100 h.p. motor with soft start switch, a pump providing the requested flow and pressure, and the 600’ hose on a powered reel, this machine was put in place to do the job.

Military uses hydraulic powered pressure washer

This is another example of a combined effort where the Cam Spray family is only a small but important part of the total machine. A manufacturer of cement trucks for the military contacted us for a hydraulic powered pressure washer system with a retractable reel for incorporation into their truck designs. A few phone calls and a trip to the plant to finalize the requirements, and we designed a package that could drop right into place. Producing 4 GPM at 3000 psi, the pressure wash system with the 50’ hose is able to wash the truck after a day of service.

Custom Sewer Jetter becomes one of the best-selling compact systems

The RCJ series sewer and drain jetter system was originally designed for a company that had a fleet of small vans. Producing 7 GPM at 4000 psi, the sewer and drain jetter works well in residential and commercial settings with 4” and 6” drain and sewer lines. The concept was to access the sewer jetter from the sliding side door of the van while it was parked curbside in a residential area. The package would also be provided with the 200DS4 a portable reel on a cart that was equipped with 200 feet of 3/8” sewer jetting hose, a shut-off valve, and nozzle. The reel would be put into place near the clean out, and the 200’ hose provided on the RCJ frame in the van would feed the portable. Power up the machine, start the jet hose in the clean out and control the water flow and jetting operation at the 200DS4 shut off valve. This machine instantly became a stock machine and one of our best sellers!

Sewer Jetting Emergency Style

Mort’s Water, a local company with a long family history in the industry, contacted us a couple of years back. They already owned several of our trailer sewer jetting systems and had a unique idea. They had purchased a used ambulance that still had lots of life left in it. They wanted us to take our skid mounted sewer jetting platform and incorporate the design into the usable space in the ambulance. Locating narrow 100-gallon tanks to a position over the wheel compartments was a huge space saver, not inexpensive but a definite need for this application. Building the skid for the power unit and the DC powered reel, the sewer jetter fell into place and was ready to respond to that first emergency call! Local law enforcement is not okay with responding with the sirens and lights to a sewer emergency!

Municipality seeks hot water sewer jet & pressure washer for hard to reach areas

A large city had issues getting into easement areas with equipment to clean short run 8” and 10” sewer lines. Equipped with this machine producing 11 GPM of hot water at 2500 psi, a ½ ton pick-up truck could easily maneuver within the easement areas. They were able to access water hydrants nearby for the water source reducing room & weight concerns. Cleaning sewer lines & manholes every 200 feet & maintaining service in areas that were hard to access before! Satisfied citizens & city workers!

Drain line maintenance in pork production facilities

If you have ever been in a pork production facility you know there is a lot going on. Mix pigs of all sizes, walkways in the range of 24” wide, drains to carry away water, feed, and some manure, and you have a recipe for clogged drain lines. This electric powered drain jetter we call the N3050J, or Narrow Jet, is an answer to this problem. Professional sewer and drain line cleaning can get expensive. The clogged drain line happens at the worst possible time and the wait to get a professional there can be an issue. A local company brought these issues to us and we responded with a solution. This company machine is set up to clean 4” and 6” drain lines on a scheduled cleaning to maintain the line. Equipped with 75’ hose, the pressure washer sewer jetter produces 5 GPM at 3000 psi. with a grenade nozzle to wash the drain line. Drain Jetting on a weekly basis to eliminate the need for costly emergency service calls.

Drain Jetting in a packing house

We received a call from the largest pork packing plant in Canada to provide a solution to drain lines being plugged with fat, bone, and other debris. We responded with a custom pressure washer sewer jetter that became the model for the CS40007BE electric powered skid drain jetter. This model was cleaning primarily 4” drain lines in a packing house setting on a daily, sometimes hourly, schedule. Producing 7 GPM at 4000 psi to blast through the clogs right away, before becoming backed up and settled in, making them too large to clear with a reasonably sized machine. The packing plant employees are maintaining the drain lines and are able to respond right away instead of calling on outside services saving time and money!

Request a quote on a custom pressure washer or drain and sewer jetter for your unique application, or contact Cam Spray to learn more.